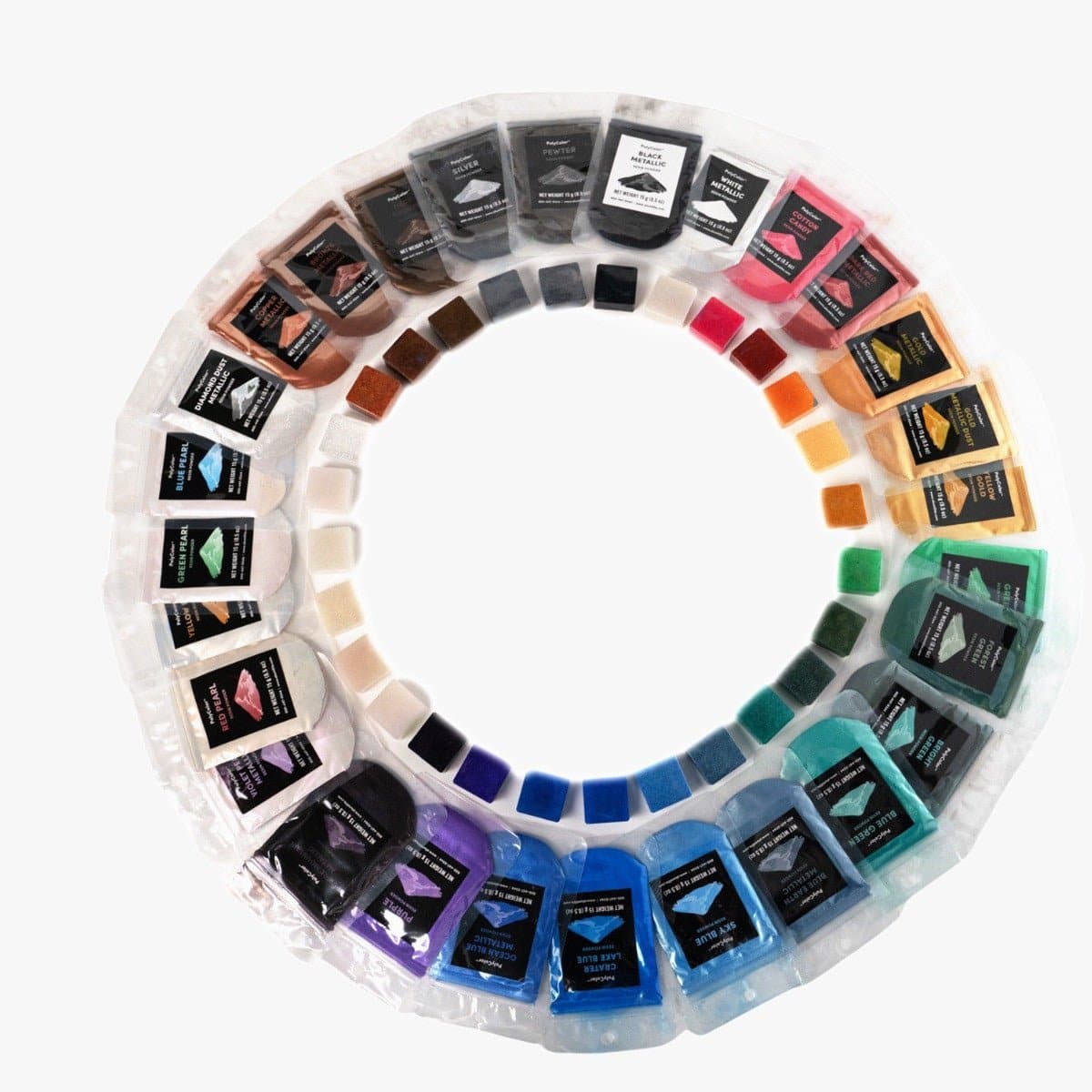

PolyColor Resin Powder 15g

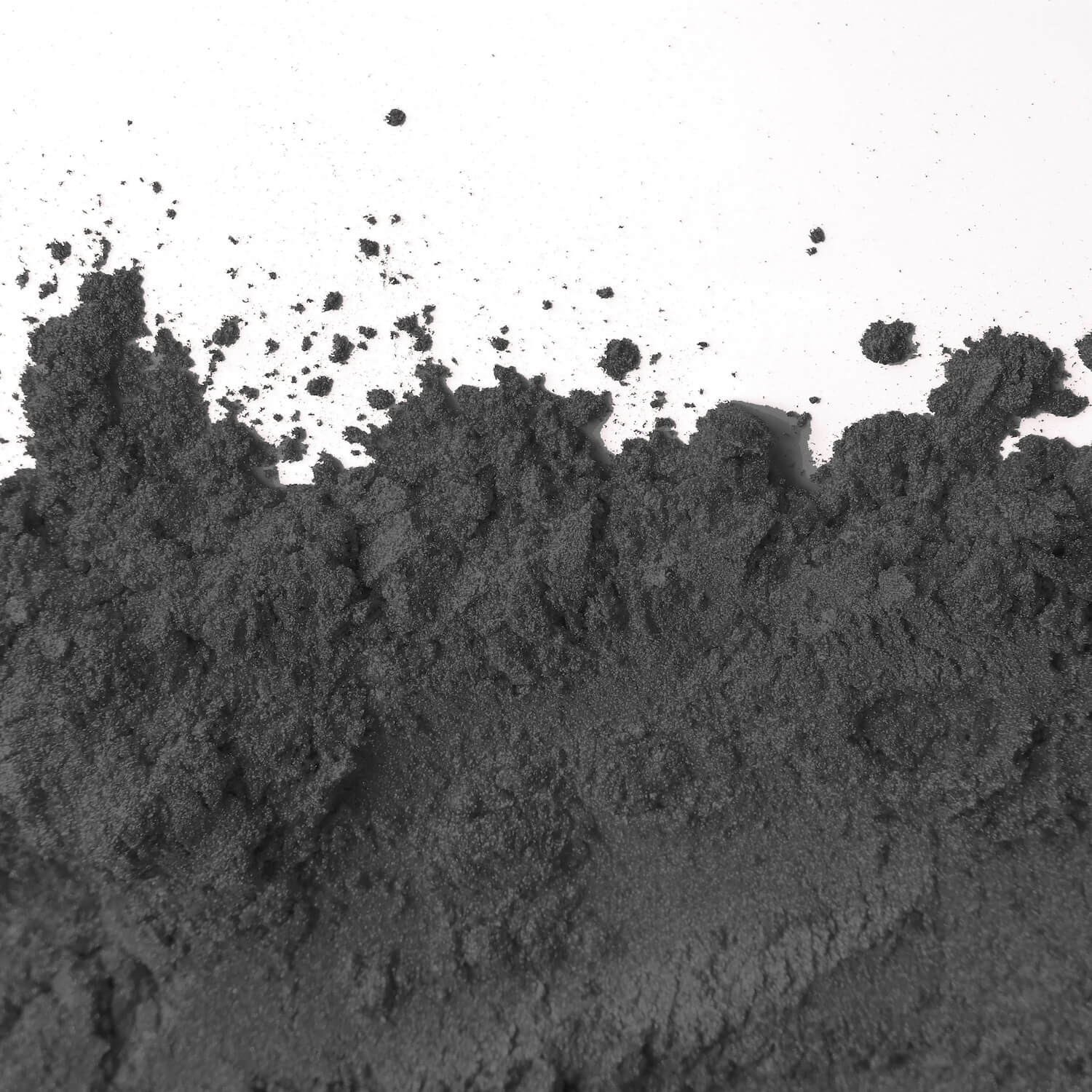

PolyColor Resin Powders produce vibrant pearlescent-effects when added to clear resins such as Alumilite Clear, Amazing Clear Cast, and Amazing Deep Pour. These powders are very fine and make a significant impact in small amounts.

Begin with small amounts and add more gradually to brighten/deepen the color until desired look is achieved. Maintain a translucent appearance by only adding small amounts. Powders can be blended for custom colors. PolyColor Resin Powders can also be used in conjunction with Alumilite Dyes.

Application possibilities include river tables, blanks for wood turning, jewelry making, coasters, serving trays, counter and bar tops, fishing lures, ornaments, frames, game pieces, tumblers, inlays, cracks in wood, and more.

Packaged in 15g resealable bags.

Product labels may vary from images shown.