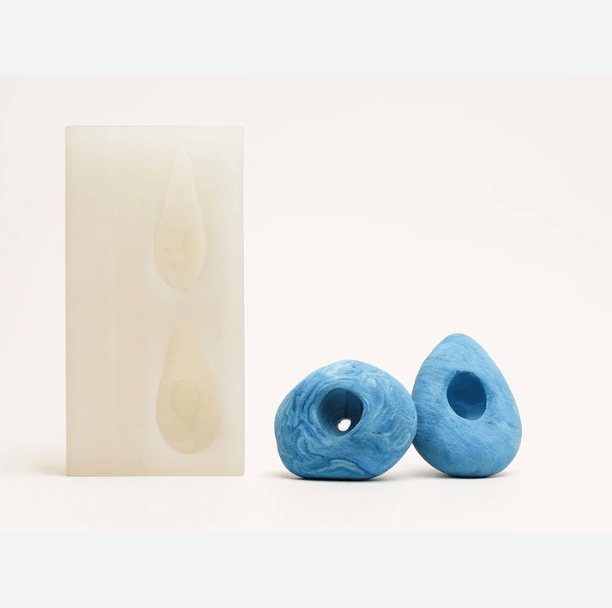

Plat 40 Platinum-Based Silicone Mold Making Rubber

Cure Inhibition:

Contamination from sulfur (e.g., sulfur-based clay), amines, tin compounds, cured polyester resin, some paints and some silicone rubbers may inhibit surface cure of platinum-cured rubbers

Features

✅ Easy to Use:

Simple 1:1 mix ratio—blend and set in just 35 minutes!

✅ Perfect Detail:

Captures even the finest textures with accuracy.

✅ Food-Safe & Non-Toxic:

Safe for culinary projects and family use.

✅ Heat & Freeze Friendly:

Withstands up to 400°F and freezer use for all your baking or freezing needs!

🚫 Skip the Hassle:

Quick, easy setup with minimal effort.

FAQ

How do I avoid air bubbles in my mold?

🫧 To prevent air bubbles, mix slowly and thoroughly to avoid introducing air. When pouring the mixture, pour slowly into one corner of your mold box and allow it to flow naturally around your master, pushing out air as it fills. If your mold has undercuts, rotate and tilt the mold to allow trapped air to escape. Additionally, degassing the mixture in a vacuum chamber is recommended if you have one available.

How do I extend the life of my Plat 40 molds?

⌛ To prolong the life of your molds, make sure to use Mold Releases, avoid leaving castings in the mold longer than necessary, and allow the molds to cool between castings. Conditioning the molds with silicone oil or Mold Release & Conditioner after each use or before long periods of storage will also help maintain their longevity.

🥕 What materials can I use Plat 40 with, and is it food-safe?

🥝 Plat 40 is compatible with a wide variety of materials, including resin, wax, soap, chocolate, sugar, plaster, concrete, and more. It is FDA food-compliant (FDA 21 CFF 177.2600), making it safe to use for molds that come into contact with food. Once you use a mold for food, it should be dedicated to food use only. Do not switch between food and other types of casting, such as resin, to ensure safety and prevent contamination.

Do I need to degass plat 40 silicone before pouring it?

⛽ While degassing is not required, it

is recommended for achieving the highest level of detail and avoiding air

bubbles in your mold, especially for intricate designs. If you're casting resin

and using a pressure pot, then degassing is necessary to ensure the best results. However, if you're not using a pressure pot, it will still work fine,

but the final mold may not look as polished or smooth as it could with

degassing.

Can I color plat 40?

🪄 Yes, Plat 40 can be mixed with pigment powders or liquid dyes to achieve your desired color. However, avoidusing oil or water-based products, as they can interfere with the curing process.

How should I store my silicones to keep them in the best condition?

❄️ Store your silicones in a cool, dark place away from direct sunlight and high temperatures, ideally between 60°F and 75°F (15°C to 24°C). Keep the container tightly sealed to prevent moisture and air from affecting the formula. Wiping the container tops before sealing can help prevent stuck caps.

What are the best conditions for pouring and displaying silicone projects?

☀️ For the best results, pour silicones in temperature-controlled environment with humidity below 60% to ensure proper curing and avoid defects. Avoid leaving your project in the mold for extended periods, as this can impact the mold's longevity. Additionally, avoid letting your epoxy or urethane exotherm excessively in the mold, as high heat can degrade the silicone and shorten its lifespan. Using Mold Release and Conditioner after casting can help extend the life of your molds by keeping them conditioned and preventing premature wear.

Need Help Getting Started?

Check out Mold Making 101 and become a pro in no time! Have other questions? Give us a call (269-488-4000) and our team of experts will assist you.

Need It Today?

Find us in store at your favorite local retailers! Be sure to check with your local store for product and stock options. Now available at:

Precision and Versatility Made Easy !

Plat 40 delivers exceptional detail replication, ensuring your molds are accurate and dependable for every project. Whether you're crafting with resin, wax, food-safe materials like chocolate, or other casting compounds, this versatile silicone is designed to handle it all with ease and precision.

It’s simple to use, featuring an easy 1:1 mix ratio and a generous 35-minute working time, making it suitable for both beginners and experienced mold makers. Plat 40 cures in 16-24 hours, providing a quick turnaround for your projects without sacrificing durability or performance.

Which Plat Silicone is Right for Your Project: 10, 25, or 40 ?

The main difference between Plat 10, 25, and 40 lies in their hardness levels, measured on the Shore A scale. Plat 10 is the softest and most flexible, making

it ideal for intricate molds with fine details or delicate materials like chocolate.

Plat 25 offers a medium level of firmness, providing a balance between flexibility and durability for a wider range of projects. Plat 40 is the firmest, best suited for molds that need to hold their shape under more pressure or when casting tougher materials like concrete. The choice depends on the level of detail and the strength needed for your project.